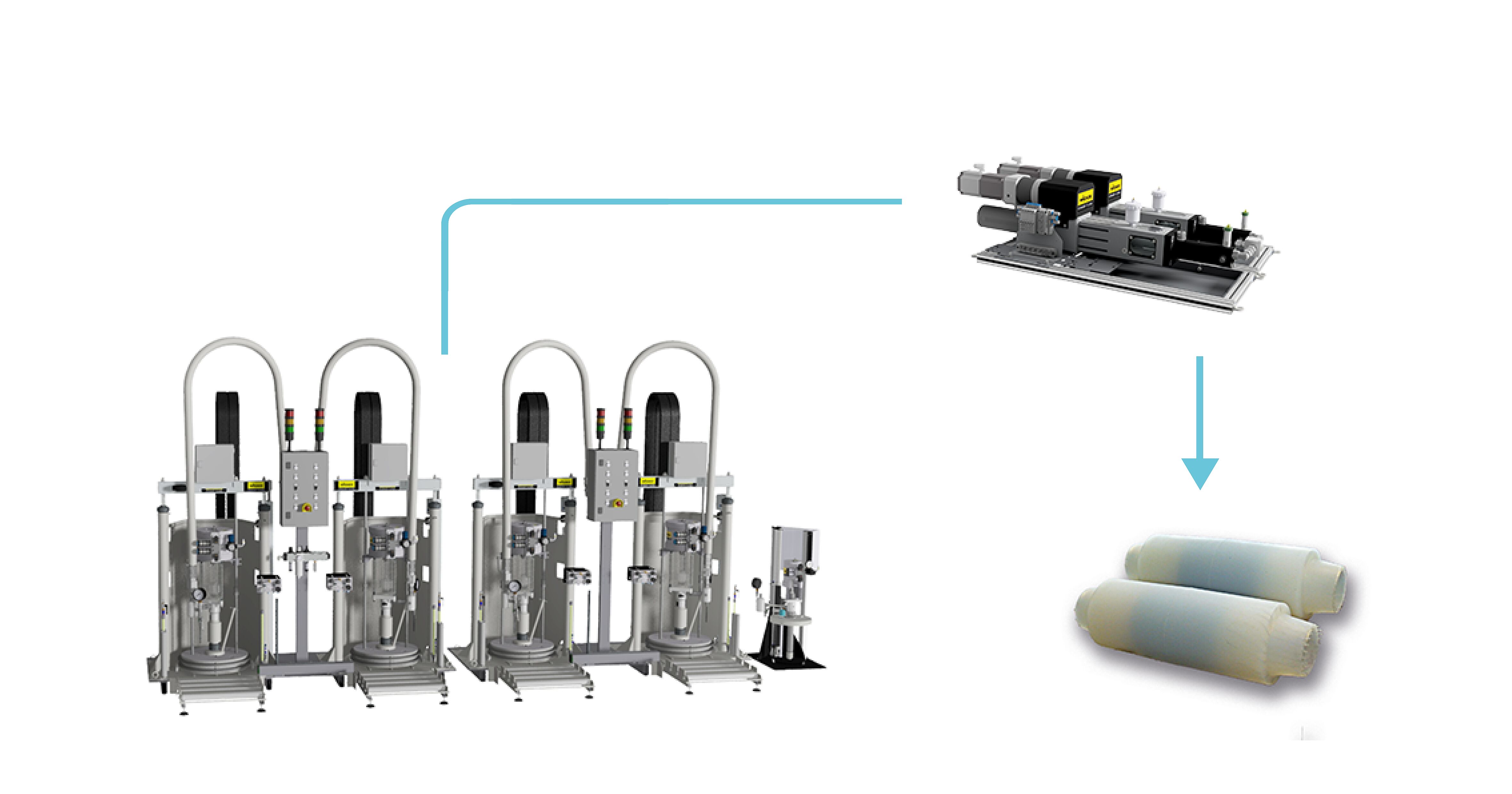

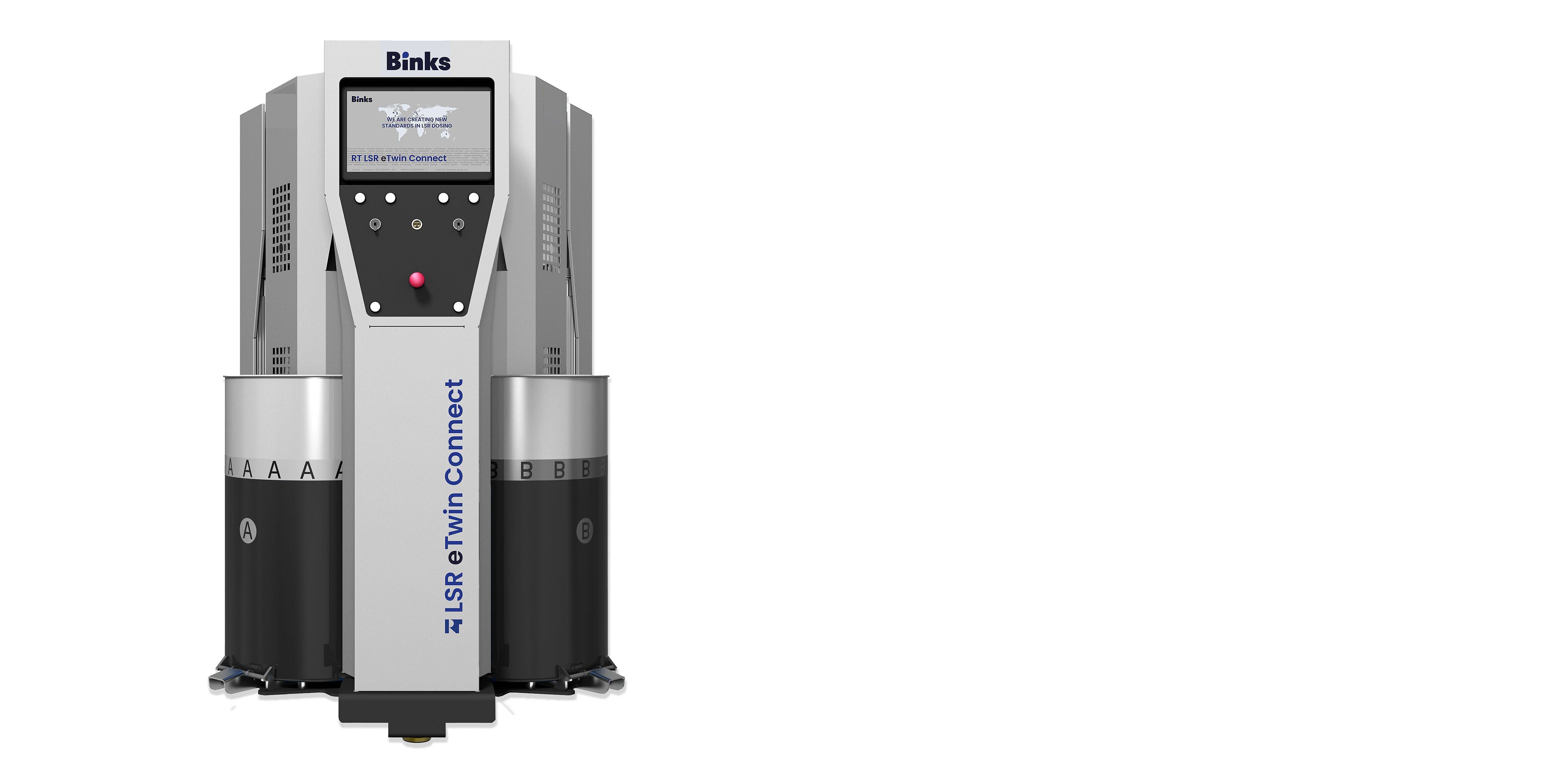

Customized LSR solutions

The requirements in the production of plastic parts are as diverse as the products themselves. The dosing technology solution must also be adapted to the specific requirements of the applications. As your partner in dosing technology, we are happy to work with you on your individual machine configuration. We can draw on a broad product portfolio and decades of experience in the processing of plastics.